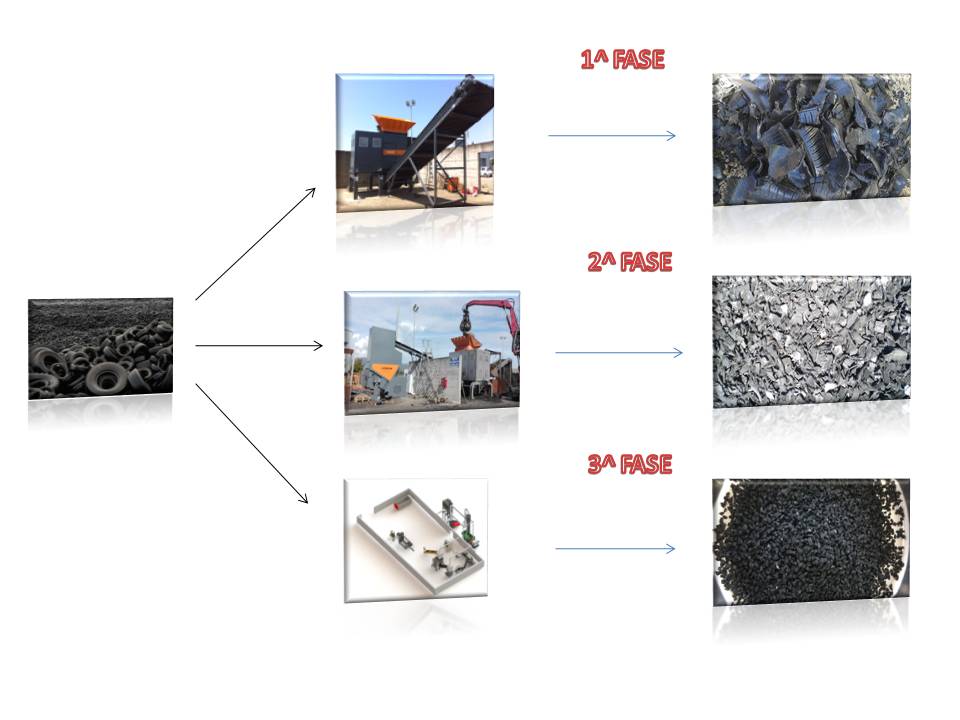

The Three Microscopic Processing Phases of the “PFU”

End-of-life tires are one of the major pollutants on our planet.

If left in nature, this material takes hundreds of years to degrade, therefore more and more companies organize themselves to manage this product which is 100% recyclable; already from an initial rough processing that feeds incinerators to produce energy, up to the minute rubber granule, used for example in the sports field, for the surfaces of athletics or football fields, as well as the inclusion of the same in the mixtures for the production of the asphalts.

Below we will explain the 3 main processing stages for end-of-life tyres:

“Ciabattato”: it is obtained through the passage of the disused tire, preferably beaded, in the “TRITONE”; The primary shredder with a single passage allows to obtain an ideal size, which is normally around 100 mm, to guarantee combustible energy for cement factories.

“Chips”: obtained by introducing the “Ciabattato” material into the secondary “ARES” shredder; the machine in question allows you to perform a second shredding, where the material will be brought to a size of about 25/30 mm where any remaining steel will be adequately removed with this step from the chip, and recovered. This product is normally used as a mix in asphalt production.

“Granulo”: it is obtained by passing the Chip, rigorously cleaned, in the “Omer Mill” blade mill; this machine will allow to obtain, through grinding at very high revolutions, a clean rubber granule ready to be marketed as a "first second" product and used for the multiple applications in urban planning, furniture, or other now essential uses in everyday life of the world of work.